-

Identifying Your Application’s Roadmap

Identifying Your Application’s Roadmap

It’s extremely important to specify an application’s roadmap during the development stage of a gearbox, which includes the environment the gearbox will be used in. Everything is theoretical when looking at temperatures, fluid, lubrication, horsepower, vibration and shock load. Unless you go out and do full life and endurance testing based on certain material and conditions, you really don’t know what will happen.

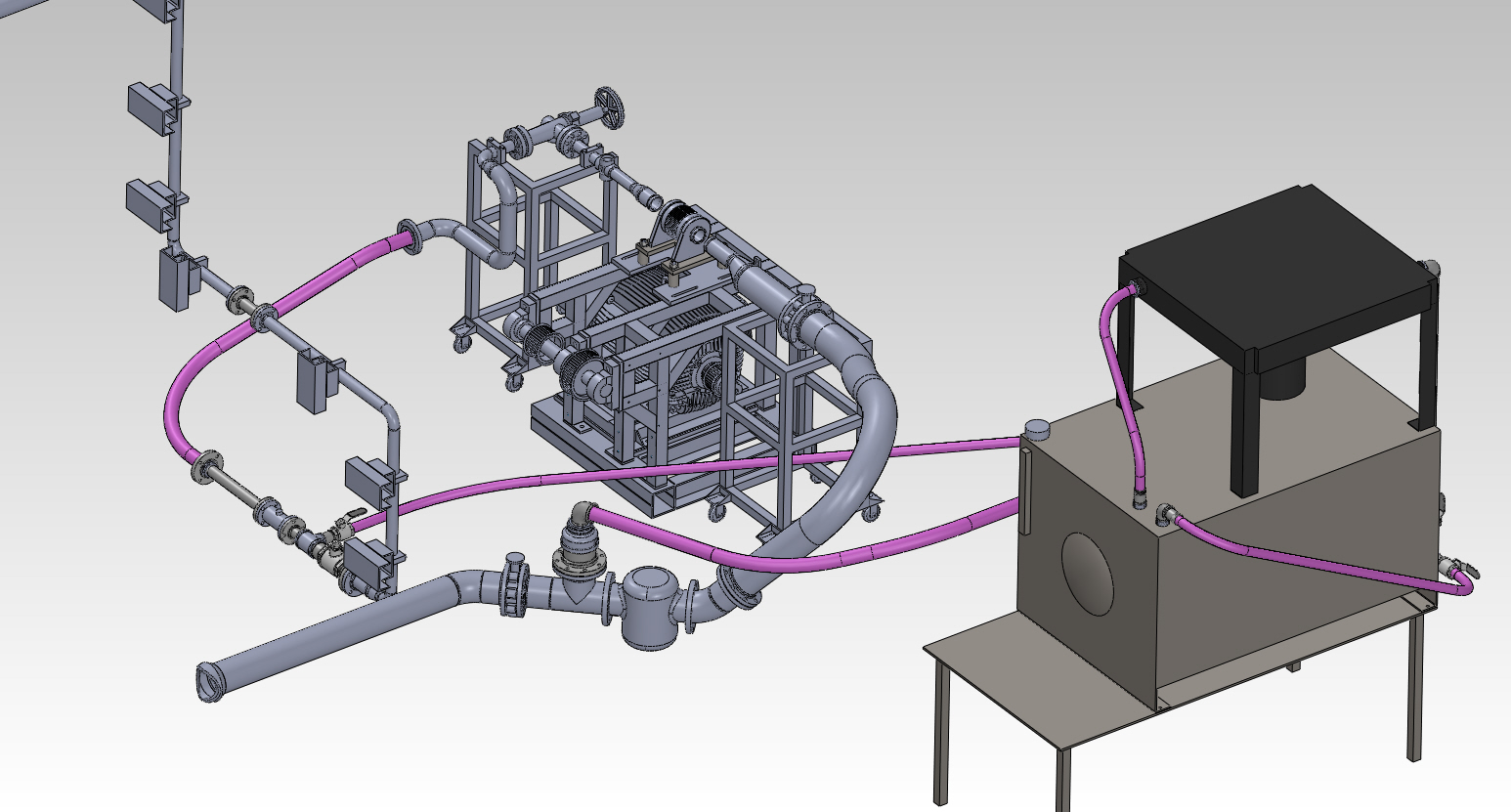

As an example, a customer came to Rj Link looking for a gearbox solution that would require a certain type of input connection being driven off a certain type of motor. The gearbox needed to be durable with a certain amount of life based on the required loading condition. Other specific requirements included speed, pressure, temperature, duty cycle, as well as certain type of operating characteristics.

After visiting the customer’s testing location, Rj Link’s engineering team utilized their expertise and knowledge to offer a gearbox solution with all of the requirements in mind. While doing a Finite Element Analysis, the team went back through to determine a reasonable life, as well as some operating characteristics and conditions that the gearbox would survive best in. The next step would be the prototype testing phase. One prototype would be used on the low end of the operating condition and another on the normal end. A third prototype would be used to step it up incrementally to find the point where the gearbox might fail. An analysis would then be done to determine what failed, to answer questions such as if a material change is needed, if there was an environment issue, a catastrophic failure or something that would be prorogated over time.

The gearbox design can often be one of the deciding factors in the success of an application. Understanding the roadmap, and providing as much information as possible during the development phase of a gearbox, the better chance for success that the gearbox will meet or exceed the necessary requirements.

1-815-874-8110

1-815-874-8110