-

Housings for Gearboxes, Pumps & Other Products

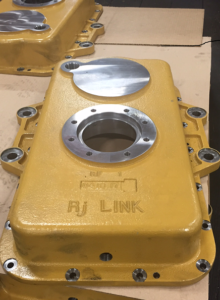

Gearbox Housings

Two typical types of housings that Rj Link International machines are castings (ductile iron and aluminum) and steel weldments.

Castings vs. Weldments:

Castings are usually preferred, especially for the larger gearboxes, because deflection of the castings will be less during system operation. If the gearbox housings bend too much then damage to the gear teeth, bearings, shafts and housings can occur. In this situation, the gearbox will need to be reinforced with some type of support structure to prevent deflection. This would be an added cost to the whole system. Weldments for larger gearboxes tend to deflect much more thus need to be larger, thicker and heavier than a casting to perform just as well. Another reason to design a housing using a casting is the final machining time will be less, and for additional orders the housings will be dimensionally more consistent from order to order.

Types of Tools:

- Foam patterns – use for 1-4 castings

- Wood patterns – use for 4 or more castings – depending on volume there are different types of wood that are used.

When the needed quantities are low, one or two sets of castings, a foam pattern can be used. This is relatively inexpensive and will result in a more rigid part. The lead time may be longer for a casting vs a weldment, but in the end you will have a much better housing and less assembly and fit issues. For quantities above 3 to 4, a wood pattern would be the next cost effective step for a casting pattern. Easy to make and modify. There are much better tooling materials for high volume applications. These materials will last much longer.

Rj Link’s Machining Capability for Castings & Weldments:

Vertical CNC: 59” L, 31.5” width, 23” height

Horizontal CNC: 25” cube size, possibly up to 45” x 30” height

- Ductile Iron Housing

- Aluminum Housing

- Ductile Iron Housing

1-815-874-8110

1-815-874-8110